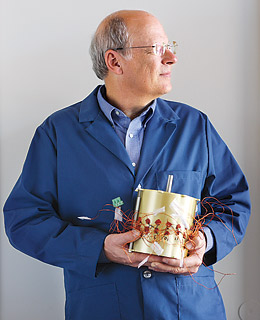

You don't need solar panels on the roof or a windmill in your backyard to go green. Boosting the efficiency of existing appliances is just as important as harnessing alternative energy sources to power them. That's why John Petro, founder of NovaTorque in Sunnyvale, Calif., decided to redesign the electric motor, which consumes about half of all the electricity used today and is found in everything from toy robots to dishwashers. Motors use oppositely charged magnets to create spin, converting electrical energy into mechanical energy. NovaTorque's motor replaces the cylindrical magnets found in induction motors with smaller, conical ones that are both lighter and more compact. The design requires 40% less steel and half as much copper wiring as a typical motor. It's also 10% to 30% more efficient. That's a massive energy saving — power plants' worth.

Though the motor was conceived in 2003, its development stalled for years because Petro didn't have the funds to manufacture it. The $40 billion motor industry is notoriously resistant to change and gave NovaTorque a chilly reception. Other potential investors simply didn't understand his breakthrough. "The motor industry is not something the venture-capital industry is interested in. They will fund the 23rd solar company before they will fund a motor company," says Petro. In July, Petro finally found a VC who got it.

Manufacturing starts next year, and yes, NovaTorque is hiring engineers.